Embossing and Debossing are two separate processes that can be used to give amazing effects.

Embossing

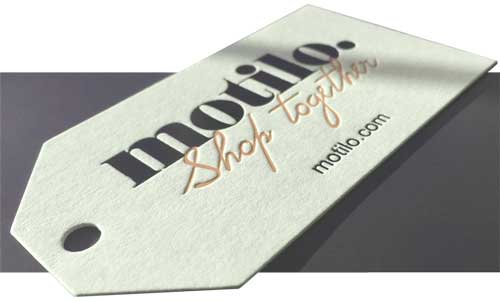

Embossing is the work at which we raise your logo or other picture to make a 3D realistic. This raised surface is accomplished by pushing a metal die into paper, card stock from underneath. The raised surface have die or foil, which include the impact on it. it can be left unprinted or unfoiled.

Benefits of Embossing

- Creates a 3D design that pops from surface

- Easier to apply foil or die stamping to an embossed design

- Can hold finer

- Better for custom stationery, business cards, and other paper promotional products

Debossing

Debossing is the opposite of embossing you are creating an indent in the material used. A metal die-stampeded on the front of the material you use, causing depressions that leave (debossed) imprint the image on your paper, card stock (or other selected material). You can choose to leave the crushing as it is (i.e. known as a blind deboss) or you can fill the indentation with ink.

Benefits Debossing

- Created dimensional depth in the design

- More comfortable to apply ink to the design debossed

- Back material is not impacted by a debossed design

- plates / Debossing generally dies less expensive than those used in embossing

- Better for custom wallets, padfolios, briefcases, luggage tags, and other leather accessories

We only use the best copper dies which give incredible detail. The most popular applications can be found on brochures, business cards, and invitations.